|

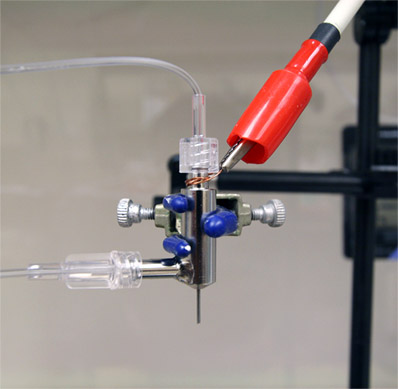

Electrospinning is a versatile technique for the production of nanofibers of many natural and synthetic materials. Electrospinning uses a high electric field to extract a liquid jet of polymer solution from the liquid reservoir. Sufficient distance between nozzle and substrate is required in order to fully evaporate the solvent. The highly charged liquid jet experiences bending and stretching effects due to charge repulsion and, in the process, becomes continuously thinner. During bending and whipping, the volatile solvent is thoroughly evaporated and the solidified nanofibers are collected on the conducting substrate. Advantages of electrospinning are the ability to control: (a) the fiber diameter from micrometer to nanometer dimensions; (b) the various fiber compositions; (c) the spatial alignment of multiple fibers. Electrospinning can produce nonwoven fiber mats with exceptional surface to volume ratios and with pores which penetrate the entire mat. Coaxial electrospinning expands the versatility of electrospinning by enabling the formation of core-sheath structured micro/nanofibers. Using the coaxial electrospinning method, different characteristics from each polymer can be combined into one fiber. Electrospinning setup is very simple and cost-effective. In a laboratory environment, electrospinning requires a high-power supply, a conducting substrate and a syringe pump. For coaxial electrospinning, additional syringe pump and coaxial nozzles are needed. Our electrospinning setup and coaxial nozzles are shown below.

|