|

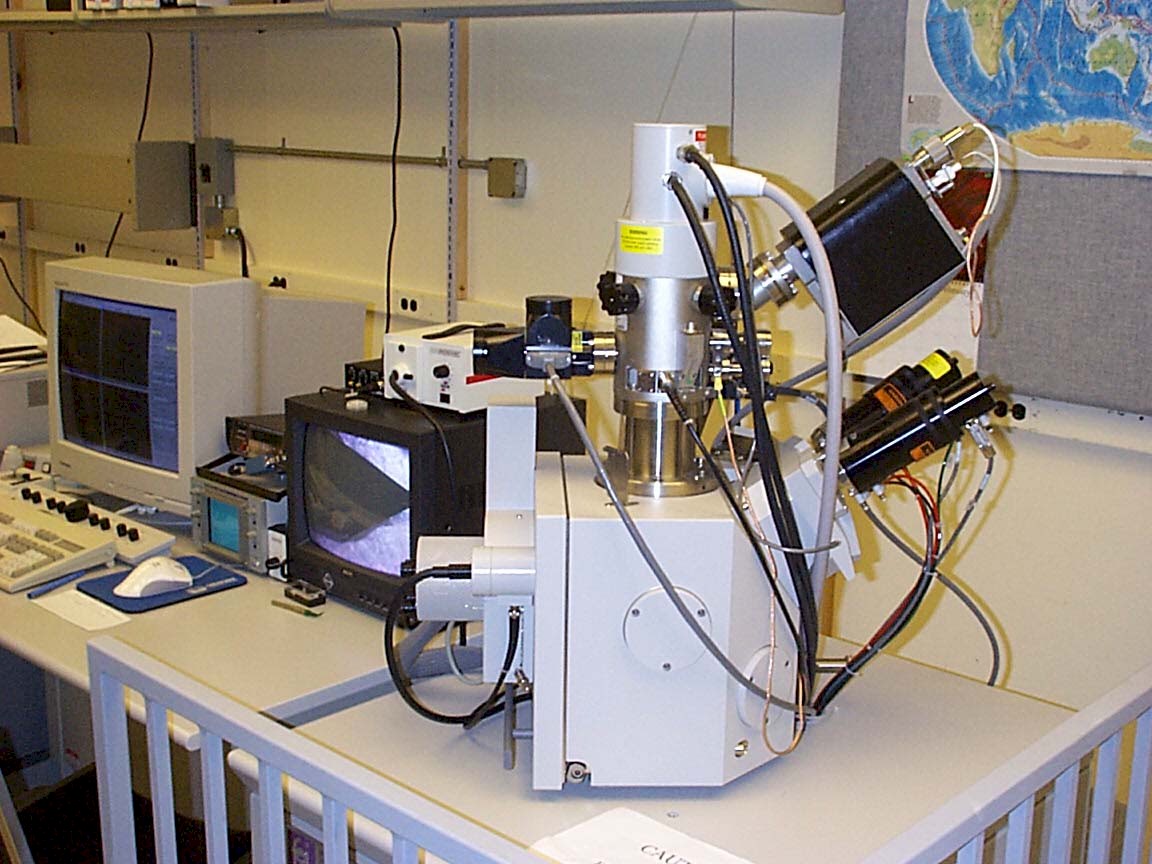

FIB 200 TEM system of FEI Company

provides better performance on overall operations of fabrication of

micro optical devices by Ga+ ion beam micromachining. This system is an advanced tool for rapid, precise

micromachining and deposition of submicron features in various

substrates and materials. It

is also a superb general purpose tool for SEM/TEM specimen cross section

preparation, high contrast imaging, grain structure analysis, high

aspect ratio probe drilling, fabrication of MEMS structures, and other

related applications. The

major system specifications include that its accelerating energy range

between 5 - 30 keV. Beam current range from 1 pA - 20 nA for 12

apertures. Beam diameter is 6 - 500 nm. Secondary electron image

resolution is 7 nm. Stage movement accuracy is 0.5 mm.

Maximum stage movement is up to 15 mm. Primary

ion species are Ga and In. It can handle up to 3 inches wafer. Two gas

injection systems are equipped. I2

is used for enhanced etch and XeF2 for insulator enhanced

etch. Other functions include an in-situ optical microscope, real time

milling monitor, auto FIB programmable milling, and selective etch.

|

Focused

ion beam (FIB) provides strong capability and tremendous flexibility of

nano-fabrication. Based on physical reaction, FIB milling can be applied

to majority of materials.

Focused

ion beam (FIB) provides strong capability and tremendous flexibility of

nano-fabrication. Based on physical reaction, FIB milling can be applied

to majority of materials.