|

An

increasing demand for micro-sensors that can operate at temperature well

above 300°C and often in severe environments (such as those in

automotive and aerospace applications, in combustion processes or gas

turbine control, and in oil industry) has stimulated the search for

alternatives to conventional Si. The research in direct formation of SiC

films on insulating substrates (SiCOI structures) in this study finds a

very promising technology for producing complicated SiC device

structures and provides an excellent alternative material solution for

robust MEMS devices operating at high temperature.

Two

kinds of SiCOI structures, SiC/poly-Si/SiC/Si3N4/Si

for bent-beam strain sensors and SiC/sapphire for electrically passive

fiber-optic temperature sensors, have been fabricated, as shown in the

attached pictures. The research work in this study extends from SiC

thin-film growth using a single organosaline (3MS) precursor and a rapid

thermal LPCVD system, photolithography and ICP etch of SiC thin-films,

as well as material & device characterization. The techniques used to

characterize the as-grown and patterned SiC thin-films and starting

substrates include XRD, SEM, AFM, Hall Effect, four-point probe, mercury

probe, FTIR, XPS, depth profilometer, UV-Visible-IR

absorption/transmission/reflection spectroscopy, and UV-Visible-NIR

fiber.

The ease

of deposition and the ability to deposit large area SiC thin-films on

many different insulating substrates make the SiCOI structures very

attractive for many MEMS applications, particularly in connection with

surface micro-machining fabrication techniques. The growth temperature

and 3MS flow rate are the two key parameters on the grain size and the

distribution of grain orientations, which determine the structural,

electrical and optical properties of the SiC thin-films and related

device performance. Moreover, the ability to use electrically passive

poly-SiC fiber-optic temperature sensors gives the unique advantages of

SiCOI for low-cost, robust, high-temperature applications in harsh

environments.  |

analysis

techniques. Additionally, electrical properties of the SiC films are

mainly measured by Hall effect. At this time, the clear object of

SiC research is trying to optimize growth process to obtain SiC films

with best electrical properties for next generation electronic devices.

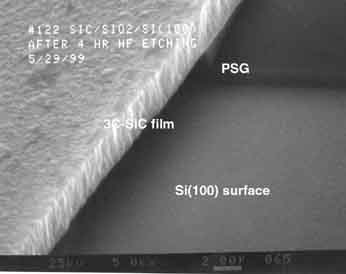

Recently, we have directly grown 3C-SiC(111) on SiO2, Si3N4

and ploy-Si surface by CVD from organosilanes (pictured left), which

makes SiC a perfect material for high temperature MEMS application. In

addition to MEMS application, SiC could also be integrated into the

current Si-based microelectronics fabrication process for gate dieletric

materials and diffusion barrier for Cu interlayers. Finally, this

process could also be used to fabricate SiC SOI structure

analysis

techniques. Additionally, electrical properties of the SiC films are

mainly measured by Hall effect. At this time, the clear object of

SiC research is trying to optimize growth process to obtain SiC films

with best electrical properties for next generation electronic devices.

Recently, we have directly grown 3C-SiC(111) on SiO2, Si3N4

and ploy-Si surface by CVD from organosilanes (pictured left), which

makes SiC a perfect material for high temperature MEMS application. In

addition to MEMS application, SiC could also be integrated into the

current Si-based microelectronics fabrication process for gate dieletric

materials and diffusion barrier for Cu interlayers. Finally, this

process could also be used to fabricate SiC SOI structure